Cold heading machine is a specialized equipment mainly used for mass production of nuts, bolts, and other fasteners.

1. The connection between the crankshaft and the body, as well as the impact connecting rod, is made of high wear-resistant alloy copper tiles, which have a large bearing capacity, long service life, and low maintenance costs.

2. The body is made of cast ductile iron 500 with added alloy, which has high tensile strength and good wear resistance.

3. Adopting a two-stage gear transmission system, with high transmission efficiency and large transmission torque.

4. Equipped with pneumatic clutch brakes to reduce motor power and energy consumption.

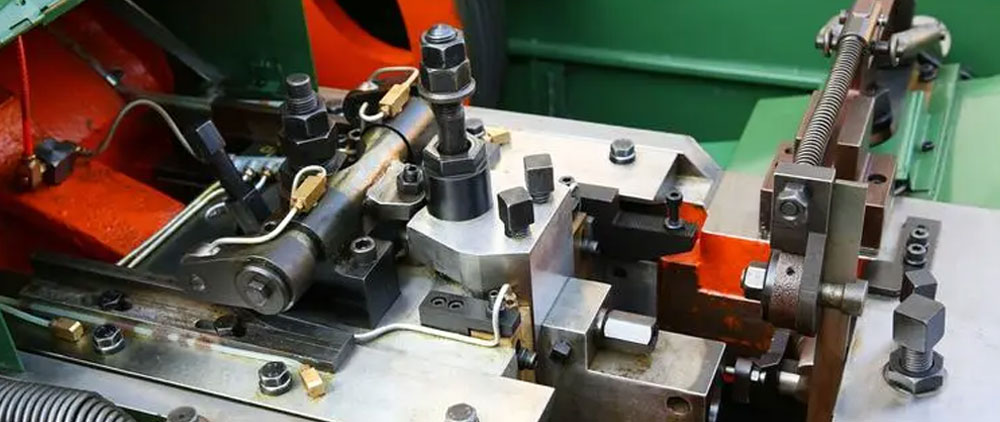

5. The cutting system adopts a guide plate to drive the cutting rod, which moves back and forth, and the cutting force is transmitted in a straight line. The force is large, stable, and has good dynamic balance.

6. The clamp system can be flipped or translated 180 degrees. Facilitating the arrangement of forming processes.

7. Equipped with a frequency conversion speed regulation device, it can achieve stepless speed regulation within a certain range.

8. Equipped with fault detectors and safety protection devices, the equipment automatically shuts down in case of failure, providing maximum protection for the equipment and molds.

9. Install a thrust device on the feeding box to improve feeding accuracy.